Lansmont Webinar: 6-Step Method_Test the product/package system (5 of 5)

Once a protective package is designed, the prototype package should be tested to assure the protective design criteria are met.

The dynamic testing inputs are linked to the expected, and ideally quantified hazards present within the intended supply chain.

Industry standards organizations such as ASTM International and the International Safe Transit Association (ISTA) develop and maintain representative distribution simulation test procedures.

This webinar will discuss the most common distribution simulation testing procedures, as well as showing how the use of instrumentation during the testing can transform pass/fail results into quantifiable protective performance metrics.

What we’ll discuss:

- ISTA test series for distribution simulation procedures.

- ASTM D4169 – Standard practice for performance testing of shipping containers and systems.

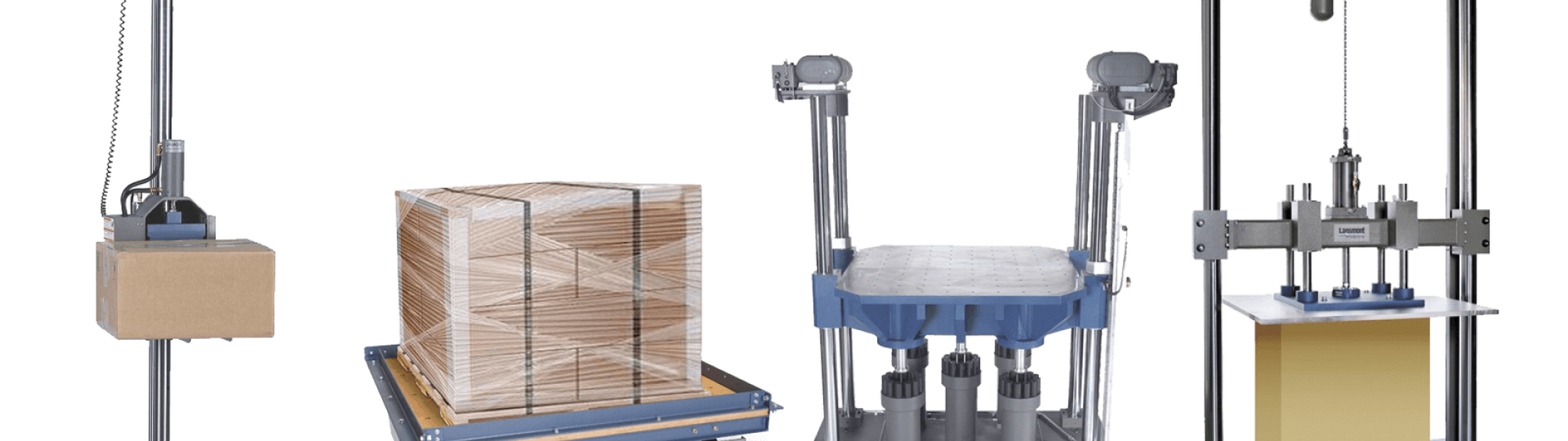

- Instrumented packaged-product drop and vibration testing.

- ASTM D6537 - Standard practice for instrumented package shock testing for determination of package performance.

Who should attend?

- Product and packaging design engineers

- Supply chain and logistics personnel

- Damage prevention personnel