Force, materials & torque

We are specialists in force, materials and torque testing solutions for quality control in production line environments and research and development laboratories.

Expert in the design and manufacture of force, materials and torque testing equipment

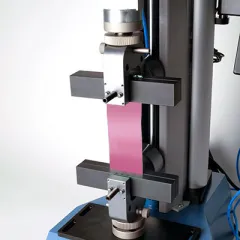

Our range of testing systems are highly versatile for conquering force and torque testing challenges of all sizes. Our engineers can design and build solutions to meet your exact testing requirements, including grips and fixtures, modified test stands or custom testing systems.

Force testing

Force testing is a way of determining how an object will react when it is subjected to tensile or compressive loads - either during its normal operation or when being pulled/pushed until it deliberately fails or breaks. These forces can be classified as tension, compression, flexure, shear and fracture. When delivered suddenly at ultra-high speed this is known broadly as 'dynamic' loading. It is typically used for cyclic-fatigue or creep testing to determine the life-cycle of materials or components.

Materials testing

One of the missions for materials scientists is to deliver more efficient processes of developing lighter, stronger and more long-lasting materials. Testing the physical strength properties of materials, in accordance with international or in-house standards, is a key part of determining their characteristics to better understand the effects of process improvements.

Torque testing

Torque testing is a way of determining how an object will react when it is being turned - during normal operation or being twisted until it deliberately fails or breaks. This rotational force can be 'dynamic' often delivered at ultra-high speed or 'static' at a much lower speed.

Get in touch to discuss your requirements and arrange a demo or training session.