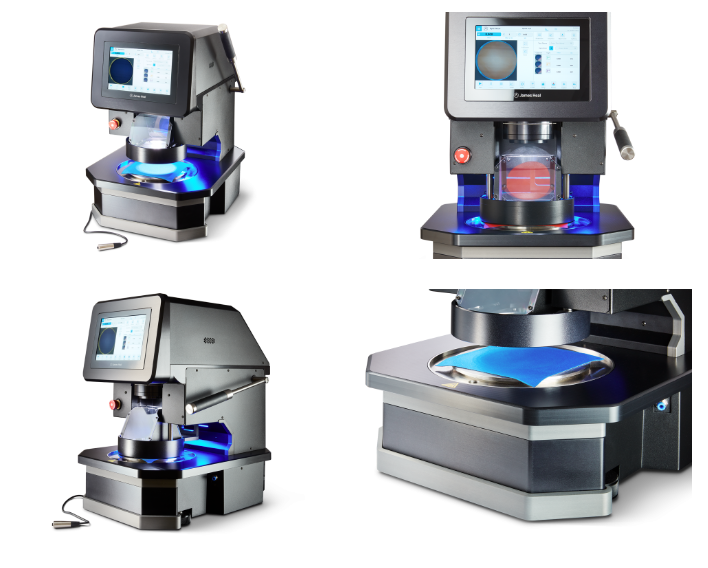

James Heal announced today the launch of its new HydroView hydrostatic head tester. Along with the recently released ‘AirPro’ air permeability tester, HydroView is the latest instrument added to the manufacturer’s performance testing line.

Manufacturer of precision textile testing instruments, James Heal, has developed an alternative solution to testing water resistance in fabrics with its new ‘HydroView’ hydrostatic head tester, for testing materials which have an end use that requires water resistance, to measure the penetration of water. This includes materials produced for a range of applications across the medical, apparel, geotextiles and nonwovens sectors - from protective gloves, diving dry suits, winter sports apparel, to fishing waders, roofing, tenting and ground sheets and more.

In the hydrostatic head test, the product application will define the target hydrostatic pressure; the lower a hydrostatic pressure measurement the more easily water can penetrate under pressure. “As more and more brands are investing in new materials and making performance claims on water resistant/waterproofing, the hydrostatic head test is one of the most common ways to test”, explains James Heal’s Technical Specialist, Sara Williams.

Sara continues, “an example of where hydrostatic pressure might be important, is testing the groundsheet of a tent. This needs a high resistance to water penetration especially when placed on saturated ground. When pressure is applied to the ground sheet by people standing, sitting or sleeping on it; water could then be forced through. Failure in this area would mean anything in contact with the groundsheet will become wet.”

This is also the case with a performance garment claiming waterproof properties, adds Sara. “You would need a high hydrostatic head value to demonstrate its defense-ability against driving wind, rain and other physical factors. Waterproof penetration testing is key to understanding the performance of a garment in adverse weather conditions.”

The testing instrument manufacturer explains that their new HydroView machine is a natural addition to their growing performance testing range, a suite of instruments designed specifically for testing ‘technical and performance fabrics’. It was developed following extensive user research around hydrostatic head testing, where James Heal’s product innovation team discovered that users were looking for an instrument that is more flexible and user friendly than what was currently available on the market.

Powered by the belief that hydrostatic head testing shouldn’t be difficult, James Heal developed HydroView to provide users with an easier to use instrument, with integrated TestWise software, a proprietary system developed in-house.

“We felt we could add value to this type of testing by introducing our popular TestWise software to HydroView,” said Neil Pryke, Innovation Director. “Our TestWise software used in this instrument is intuitive, has clear navigation, and requires minimal user training. An integrated camera captures an image when the user detects a drop, this supports live and post-test analysis and is further enhanced by the zoom and mark features,” added Neil.

James Heal claims to have also simplified water management with HydroView. “An integrated pump automates the filling and emptying of the instrument for testing, and enables fine adjustment of water levels. The machine includes a wastewater drawer, removing the need for any additional plumbing which saves time and cost when conducting tests,” explained Neil.

Other key features of the HydroView include:

- Start testing straight away with easy-to-use TestWise software: a 10” touchscreen, allows the user to choose from pre-loaded standards or create their own. Test reports are easy to view and analyse on screen, and can be customised for export to Excel or PDF;

- Integrated camera system, with a ‘zoom and mark’ feature, capturing an image when the user detects a drop, supporting live and post-test analysis;

- Vertical clamping ensures an effective seal without distortion, even on thicker specimens, for accurate and repeatable testing;

- Ability to test across pressures from 0-10,000 mbar, making it suitable for testing even the most high performance waterproof system;

- Large, illuminated test bed, which accommodates both multi-layered fabrics and sheet substrates;

- Feature to ‘pause’ a test during testing;

- Innovative safety guard arrangement enables users to hold specimen in place without hands being near the pneumatic clamps when engaged for testing;

“James Heal’s focus is to make testing simple, fast and intuitive; for greater throughput, and accurate, consistent and reliable results. We are extremely proud of what we’ve achieved with HydroView, and our wider performance testing range. We are equally excited to be able to release it to the market now, after a significant development process over the last two years”, concluded Neil.